![]()

Two Good Food Institute grants aiming to reduce costs of cultivated meat production through:

1

Prototyping sensors for in-situ measurements of biomass, nutrient, and metabolite quantities.

(RS1)

2

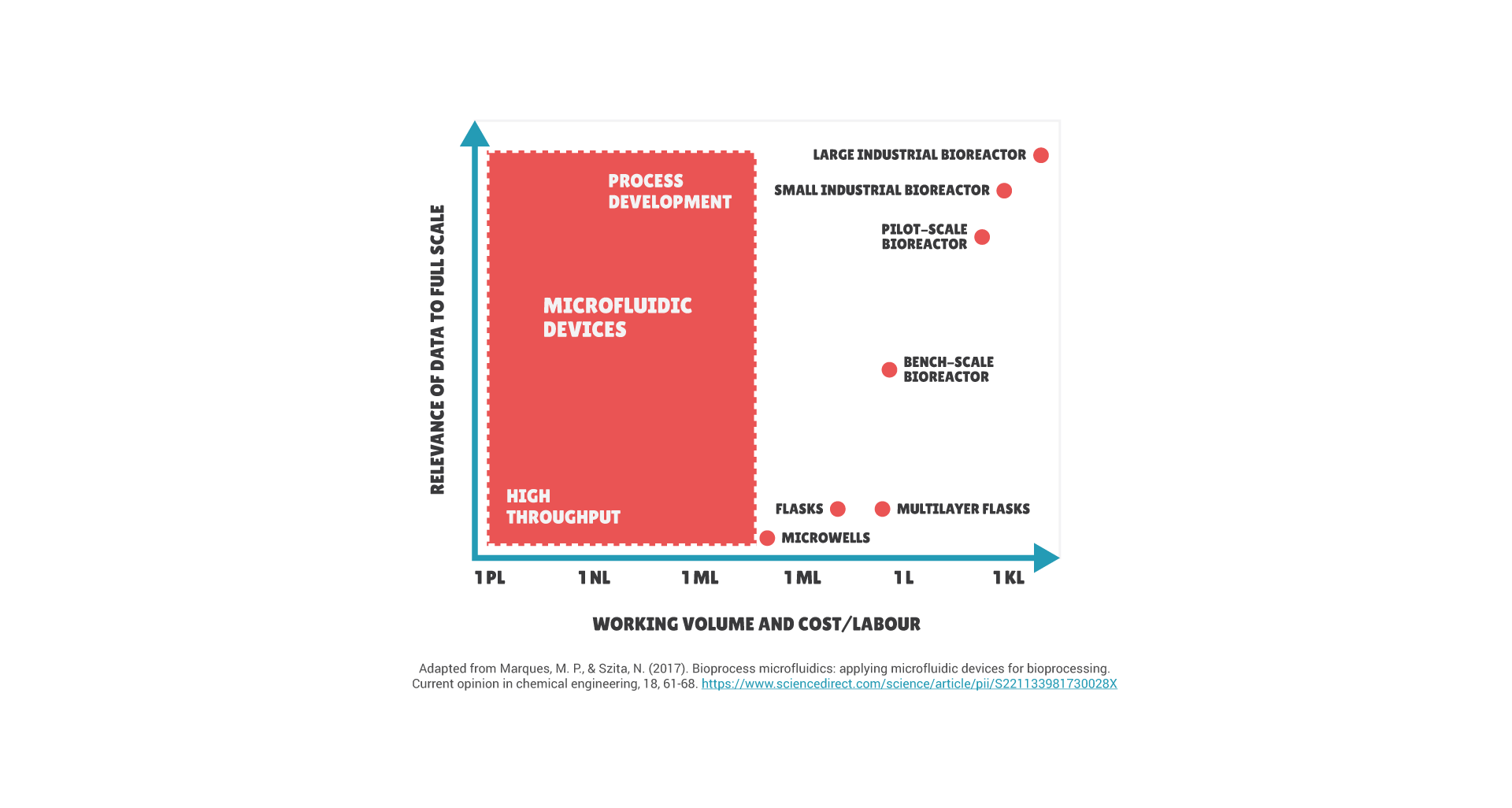

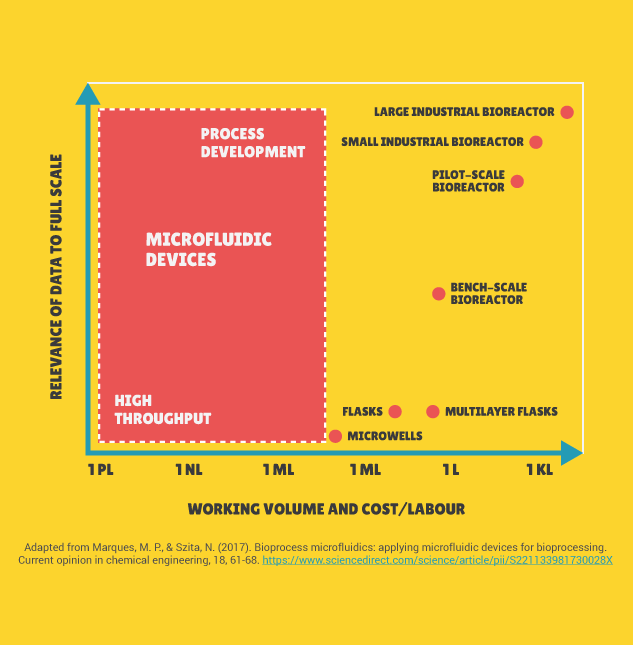

Implementing lab-on-a-chip strategy, combining sensors and microfluidic devices- as a scale-down approach to solve process problems before scale translation.

(RS1)

3

Using mathematical modeling coupled to experimental validation to identify the most efficient configuration for integrating sensors into stirred-tank bioreactors.

(RS2)

4

Developing and optimizing the next generation of biomass, nutrient, and metabolite sensors and enables their configuration in bioreactors.

(RS2)

SPECIFIC OBJECTIVES OF THE PROJECTS ARE:

RealSense1 (RS1) aims to develop a new generation of low-cost sensors for monitoring of cell culture parameters: biomass concentration, nutrients (glutamine and glucose) and metabolic waste products (lactate and ammonia).

Specific objectives (SO) in RS1 are:

1

SO1 – RS1: Develop individual sensors as flexible electronic devices, probes or microfluidic chips and devise readout systems.

2

SO2 – RS1: Develop microfluidic cell culture device for lab-on-a-chip (LOC) approach.

3

SO3 – RS1: Test the LOC cell culture device with integrated sensors.

RealSense2 (RS2) will use mathematical modeling coupled to experimental validation to develop and optimize sensors for biomass & nutrients/metabolites in media and enable their integration into commercial bioreactors. This will provide better bioprocess control, in-line monitoring and when combined with filtering, can enable media recycling which may reduce overall costs of proliferation steps for cultivated meat production.

Specific objectives (SO) in RS2 are:

1

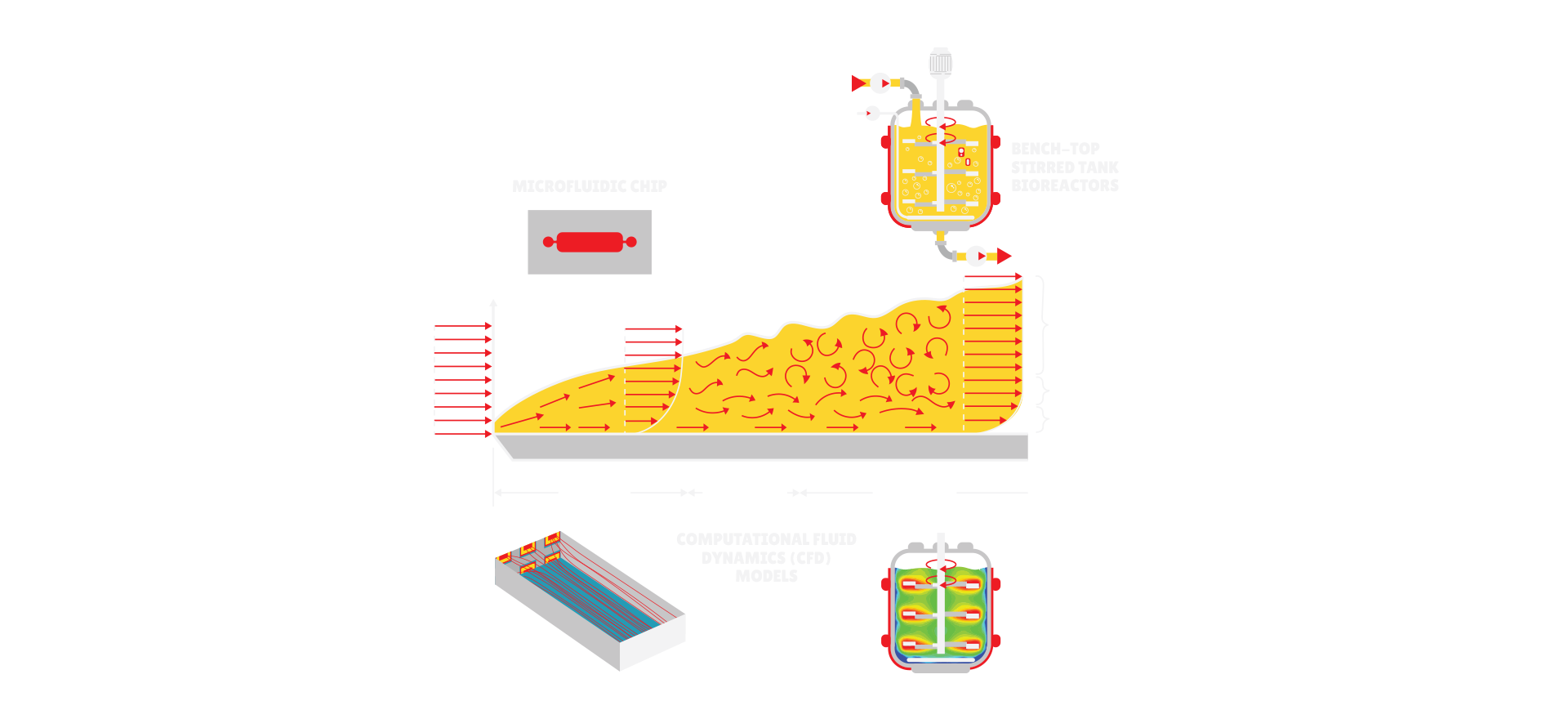

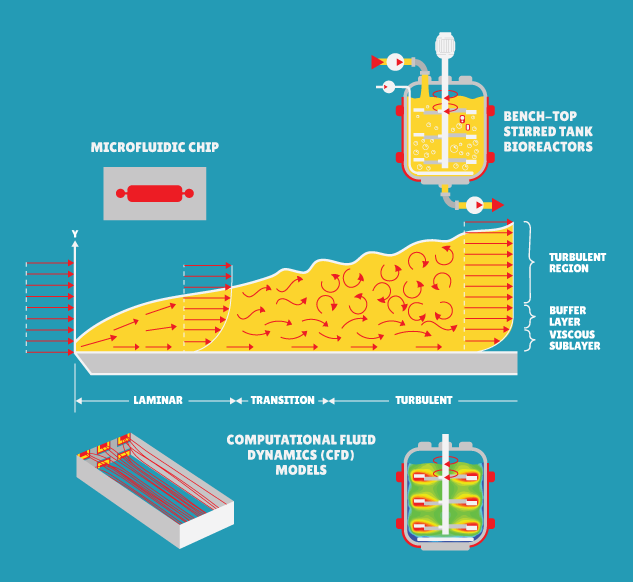

SO1 – RS2: To identify the most efficient configuration for integrating sensors into the stirred tank bioreactor through coupled mathematical modeling, computational fluid dynamics (CFD) and experiment.

2

SO2-RS2: To develop and fabricate integration-ready sensors of biomass/nutrient/metabolite sensors ready for integration (TRL5-6) into the bioreactor. To integrate the fabricated sensors into the bioreactor following design identified through the CFD models as the most efficient.

3

SO3-RS2: To test the bioreactors with integrated sensors using commercially-relevant cell types provided by the advisory members. Importantly, cells of different origin will be tested i.e. mammalian and invertebrate.